Abstract: Stable power supply is the basis for ensuring the normal production of enterprises. Therefore, how to ensure the normal operation of power equipment is an issue that enterprises focus on. Temperature is an important parameter that characterizes the normal operation of power equipment . During the operation of power equipment, if over-temperature operation occurs, it will reduce the performance and service life of the equipment, cause equipment failure, affect the normal operation of the power grid, and even cause electrical fires, resulting in huge economic losses. Collect the real-time temperature of the key power equipment contacts, overcome the shortcomings of the wired temperature monitoring system such as multiple lines, complex wiring, difficult maintenance, and high-voltage isolation, combine temperature sensors with wireless communication technology, and combine Internet of Things technology with power automation technology to realize an intelligent wireless temperature measurement system solution. The wireless temperature measurement system has the characteristics of simple and reliable structure, good scalability, and flexible deployment. It can be combined with the deep needs of the industry and other technologies to further promote and apply it in industrial power distribution systems.

Keywords: Chemical industry temperature measurement Passive wireless temperature measurement Electrical temperature measurement Temperature measurement system

1 Analysis of Temperature Measurement Requirements for Power Distribution Systems in the Chemical Industry With the rapid development of China’s economic construction, many chemical companies have emerged. The chemical industry is a large and complex industrial production system, and the stable and reliable power supply and distribution of enterprises is the basis for ensuring normal production. The power distribution system of chemical enterprises has the following characteristics: (1) High reliability requirements. Chemical production is continuous. Once the power supply and distribution system has problems and causes production interruption, it will cause waste of raw materials; ( 2) The load is large and relatively stable. The chemical production equipment has high continuity. The entire power supply and distribution system is relatively stable and has little change; (3) Gradually expand the capacity. The expansion of the production scale of chemical enterprises and new reconstruction projects will bring new power loads; (4) There are many high-power motor loads, and a large number of motors are required to provide power sources for production activities. The chemical power supply and distribution system uses a large number of

electrical equipment such as medium and low voltage switchgear and motors. The high requirements for automation and continuous production not only put forward higher and higher requirements for the reliability of its power supply, but also put forward higher requirements for the stability and reliability of key power distribution and motor equipment in the steel industry system. In industrial systems, temperature is an important parameter that characterizes the normal operation of equipment. With the continuous growth of industrial power load, in order to avoid emergencies caused by equipment heating, automatic temperature monitoring has become an important part of industrial safety production. Electrical equipment in chemical production usually works at high voltage and high current for a long time. Certain defects in the equipment will cause abnormal temperature rise of equipment components. The vicious cycle of temperature and contact resistance value will eventually cause the equipment to fail to work properly or even burn out. Excessive temperature may cause combustion, explosion, or even equipment damage or quality accidents. Due to limited fault testing methods, high-voltage electrical equipment is more difficult to detect, especially in the switch cabinet. As the temperature rise time increases, the temperature over-limit point will increase the degree of oxidation due to heat, which may cause the burning of busbars, contacts, and contacts, and cause sudden power outages in downstream large-scale power supply lines or important power equipment, causing huge direct and indirect economic losses. In recent years, the rapid development of sensors and the Internet of Things, online monitoring of equipment, and big data analysis technologies, combined with the characteristics and needs of the chemical industry, the research and application of new technologies have provided new solutions to solve such problems. Summary of application solutions and project cases A polymer synthesis company insists on scientific and technological innovation, and has mastered a large number of independent intellectual property rights in the fields of new environmental protection, new materials, new energy, etc. It has broken many foreign technology monopolies in new environmentally friendly refrigerants, fluorine silicon high-tech materials, ion membranes, etc., and has achieved domestic substitution. It is an excellent supplier of well-known domestic and foreign companies such as Gree, Midea, Haier, Hisense, Daikin, Sanjiang, and Changhong. At present, the company firmly grasps the major opportunities of the central supply-side structural reform and the transformation of new and old kinetic energy in the province, closely focusing on the main line of scientific and technological innovation, and striving to create a new engine of “two substitutions” and “intelligent manufacturing”, which has brought vitality and vigor under the new normal of the economy, and its operating efficiency continues to rise. The entire factory power distribution 10KV system adopts single busbar segmentation, and the 2 sections of incoming lines are mutually standby; the capacity of each section of incoming lines is designed according to the capacity of 12500KVA, which can meet the production and operation needs of the entire factory area. Only 2 of the 3 circuit breakers of the 2 incoming lines and the bus tie can be closed, and the bus tie is equipped with a standby automatic throw device. The motor circuit requires separate control, and the cabinet top small busbar closing, control busbar, and device power supply require a double small busbar. The 0.4KV system uses transformers for separate operation, with a bus tie cabinet in the middle , and anti-parallel interlocking, and the bus tie is equipped with a standby automatic throw device. The main power supply of the secondary load of the process load is drawn from each busbar section, and the standby power supply is drawn from the factory box transformer. The main power supply of UPS, DCS, and control room is drawn from the 1# transformer busbar section, and the standby power supply is drawn from the emergency busbar section (the emergency busbar section is equipped with a dual power conversion switch, the main power supply is drawn from the 2# transformer busbar section, and the standby power supply is drawn from the 630A circuit breaker of the factory box transformer).

This project conducts temperature monitoring on key electrical connection points in 10Kv high-voltage cabinets and 0.4Kv low-voltage cabinets in the high and low voltage distribution rooms of the factory area. The project requires that the temperature measurement products can operate stably for a long time, and realize local temperature monitoring and alarm in the distribution room and remote temperature monitoring. After technical comparison, the solution of using wireless passive temperature sensor + temperature acquisition and display

device + temperature monitoring system is used to accurately collect temperature signals of key parts. Through the wireless temperature measurement and monitoring system of the control center, the real-time monitoring of temperature signals, accurate positioning of over-temperature parts and equipment, over-temperature alarm, ensure the life of key equipment and production continuity, and reduce and avoid the risk of potential accidents . In addition , the temperature measurement system realizes the mobile operation and maintenance of temperature measurement signals. It can not only monitor the temperature of key equipment in real time through smart phones, but also automatically send out alarm signals when over-temperature occurs, and push them to the smart phone terminals of specific responsible personnel in time, so as to realize efficient problem handling, greatly reduce the risk of accidents

of distribution devices and electrical equipment, and ensure power supply reliability, production continuity and safe production.

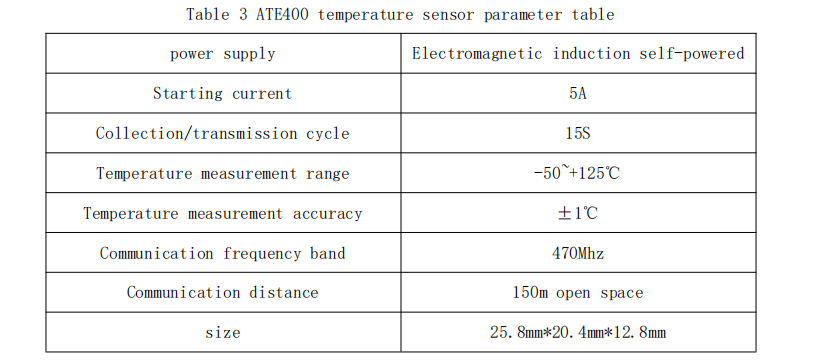

2.1 Wireless passive temperature measurement: temperature sensor + Sub-1G After technical comparison, the ATE400 passive wireless temperature sensor was selected for temperature measurement of key parts of high and low voltage switch cabinets. Its main performance parameters are shown in Table 3 .

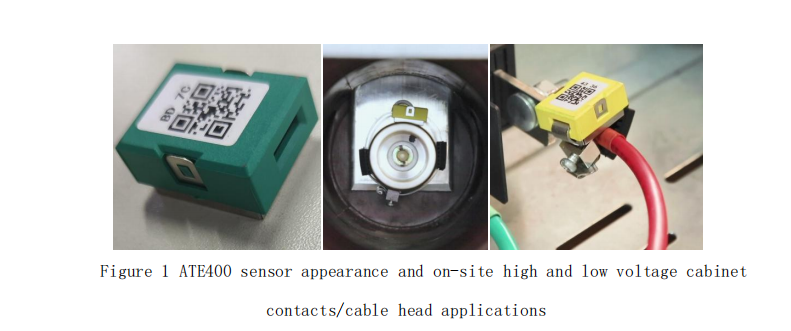

The ATE400 passive wireless temperature sensor uses primary current for induction and direct contact with the measurement point to ensure high-performance and accurate temperature monitoring. In addition, the ATE400 is very small and does not take up space, making it easy to install, debug and maintain. The ATE400 wireless communication uses Sub-1G

communication technology to ensure reliable and powerful communication capabilities. The picture of ATE400 and the scene in the project application are shown in Figure 1. Each loop of this project is equipped with 6 temperature sensors, totaling more than 3,000.

Post time: May-31-2024