Temperature can reflect the operating status of the equipment

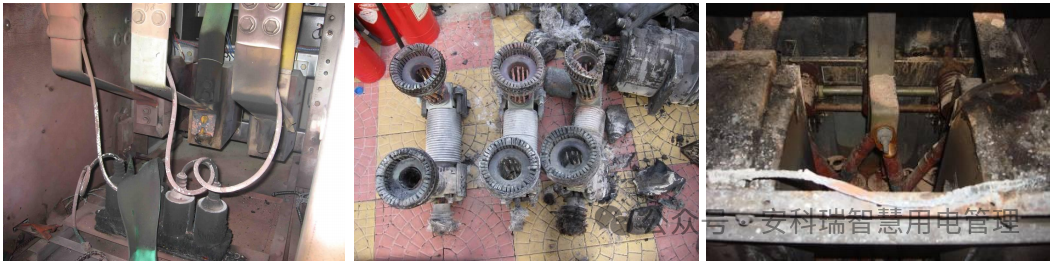

As long as various electrical equipment is connected to the power system and passes a certain current, a certain amount of heat will be generated and the temperature will rise. In the power system, many major accidents are caused by overheating of electrical equipment. If the hidden dangers of overheating of electrical equipment can be discovered in time, maintenance or repair measures can be taken in time to eliminate the hidden dangers of faults, the operation accidents of the power supply system can be greatly reduced and the reliability of power supply can be improved. Therefore, it is very important to timely discover the overheating parts of electrical equipment and correctly analyze and judge them.

Causes of high temperature of electrical contacts

① The on-site environment is more complex than the test, and long-term on-site operation has a cumulative effect of temperature rise.

② There are differences in the expansion effects of metals of different materials at the joints. When expanding at high temperatures, they are slowly plastically deformed under the influence and restriction of stress, causing tiny gaps at the joints.

③ Temperature changes cause oxidation corrosion at the joints and increase contact resistance.

④ The contacts move repeatedly, and the pressure of the tightening bolts at the connection is unreasonable, resulting in deformation of the contact surface, reduced contact area, and increased resistance.

⑤ The purity of the conductor raw materials is not enough, resulting in the conductivity of the conductor material not meeting the requirements.

⑥ During the processing, connection, and installation of the busbar, the contact surface of the busbar is not properly processed and not smooth enough, which reduces the effective contact area, increases the contact resistance, and generates heat.

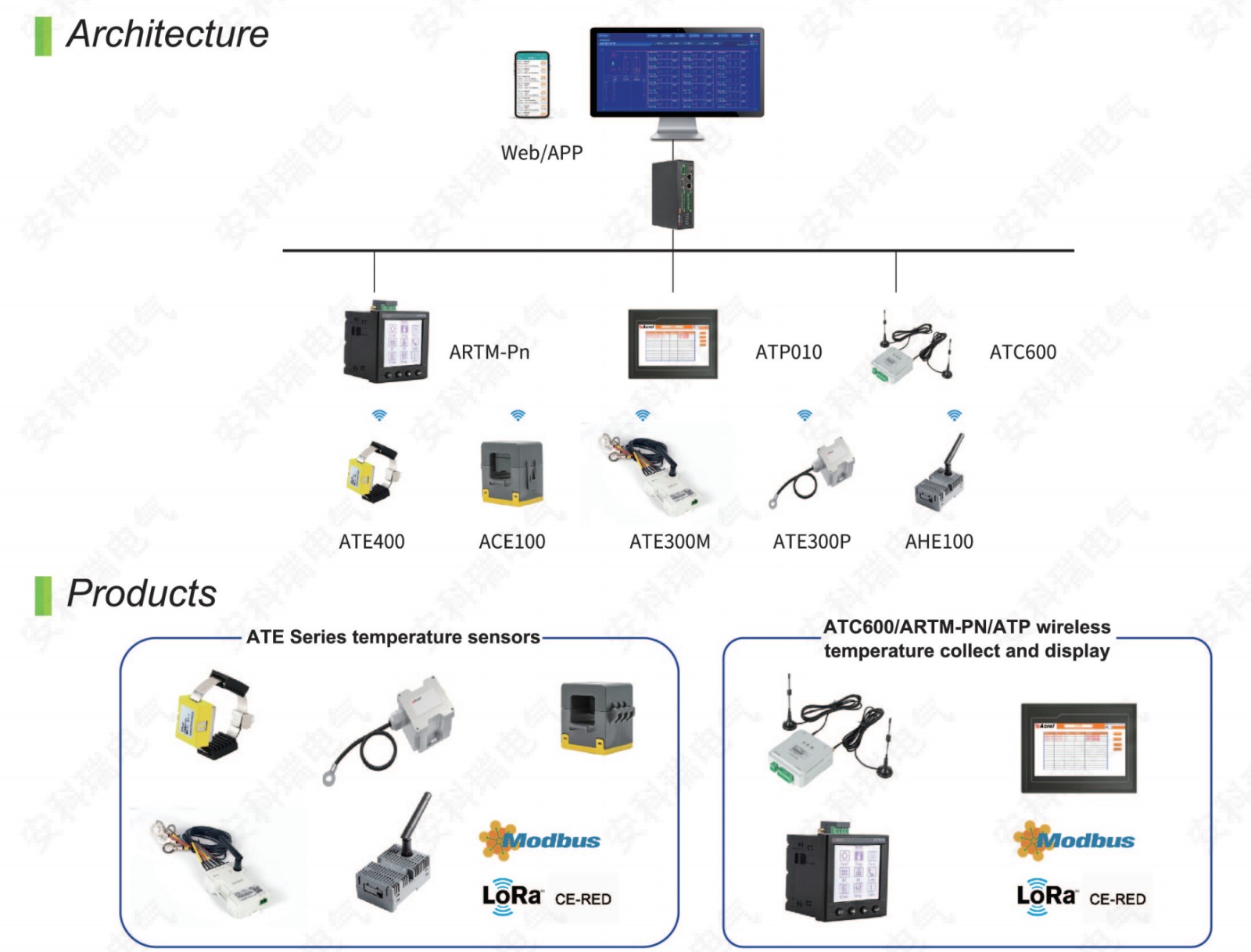

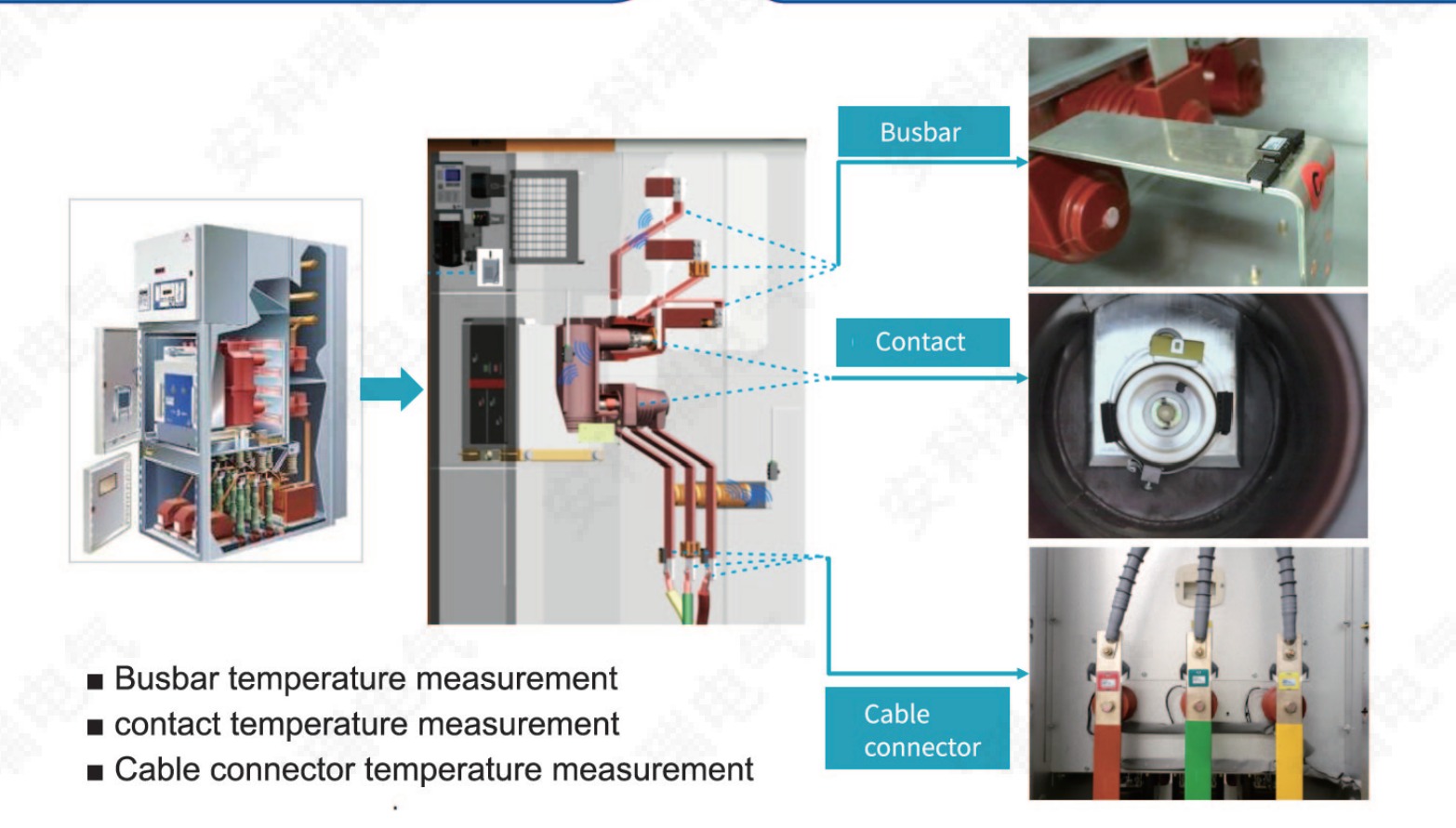

Setting

ARTM series electrical contact online temperature measuring device is suitable for temperature monitoring of cable joints, circuit breaker contacts, knife switches, high-voltage cable intermediate heads, dry-type transformers, low-voltage and high-current equipment in high- and low-voltage switch cabinets. It prevents excessive contact resistance and heating caused by oxidation, looseness, dust and other factors during operation, which may become a safety hazard. It improves equipment safety, reflects the equipment operation status in a timely, continuous and accurate manner, and reduces the equipment accident rate.

Post time: Feb-11-2025